Includes:

- Electrodynamic circulation for uniform temperature

- Temperature uniformity ± 10 deg within the work dimensions of the bath

- Less distortion plus protection from thermal shock due to preheating properties unique to molten salt

- Automatic heating and temperature control systems.

- Complete outer furnace shell (casing) for safety and strength

- Constructed with 6″ tile pots

- Air cooled transformer with external switch to easily change secondary voltages

- Prewired cubicle

- Manual or automated furnace covers

Type HCRE and HHRE with “over the top” electrodes

HCRE Temperature range 900 – 1700F

HHRE Temperature range 1700 – 2350F

Features Include:

- Removable electrodes can be changed without emptying or rebuilding furnace.

- Electrodes are “sealed” by removable refractory shapes extending usable life by reducing oxidation.

- Salt surrounds work to eliminate scaling and pitting.

- See Data sheet CP-10 PDF for further details

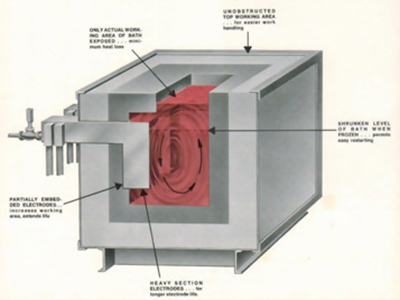

Type HCSE and HHSE with “submerged” electrodes

HCSE Temperature range 900 – 1700F

HHSE Temperature range 1700 – 2350F

Features Include:

- Ceramic pot furnaces with submerged electrodes provides long life and trouble free service with periodic maintenance.

- Electrodes, embedded below the salt line are sealed against corrosive attack at the air-salt interface.

- Salt surrounds work to eliminate scaling and pitting.

- See Data sheet CP-20 PDF for further details

TYPE “HC” Aluminum Dip Brazing furnaces

Temperature range: 1050 to 1150F

- Fast brazing in minutes

- All joints brazed simultaneously in a single immersion

- Alloy “over the top” electrodes

- Removable electrodes can be changed without emptying or rebuilding furnace.

- Temperature uniformity assured by electrodynamic circulation

- Selective heating with partial immersion

- See Data sheet CP-10 PDF for further details